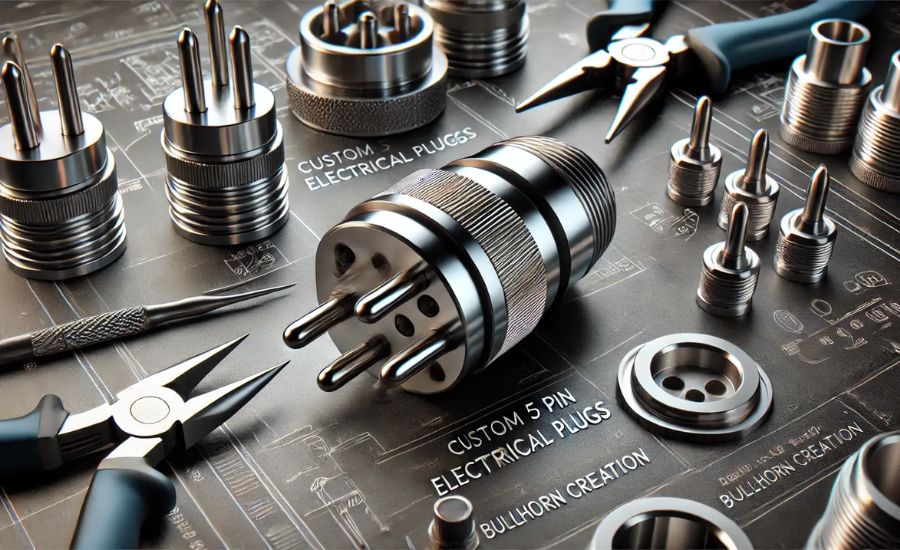

Introduction to Custom 5 Pin Electrical Plugs Bullhorn Creation

In an age where connectivity is paramount, the role of electrical plugs cannot be overstated. Particularly, custom 5-pin electrical plugs have become essential in various applications, from audio equipment to industrial machinery. This article will delve into the characteristics and functionalities of these plugs, explore their significance in various sectors, and illustrate their application in devices such as bullhorns.

What are 5-Pin Electrical Plugs?

5-pin electrical plugs are connectors that facilitate the transmission of power and signals between devices. The design of these plugs allows for multiple connections in a single interface, making them versatile for various applications. Typically, these plugs consist of five pins, each serving a different purpose, which might include:

- Power Supply

- Ground Connection

- Audio Input/Output

- Control Signals

- Optional Functionality (e.g., lighting control or feedback signals)

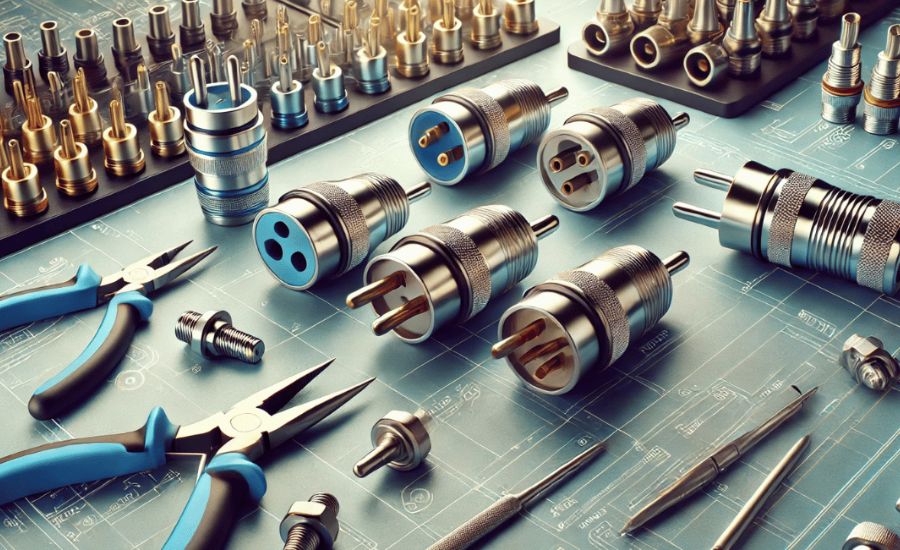

The Design and Construction of 5-Pin Plugs

Custom 5-pin plugs are fabricated to meet specific needs, often incorporating materials and designs that enhance durability and performance. Common materials used include:

- High-grade plastics for housing

- Copper or gold-plated contacts for better conductivity

- Weather-resistant coatings for outdoor applications

Dimensions and Specifications

Specifications can vary widely, depending on the application. Some aspects include:

- Pin configuration (the arrangement of pins)

- Voltage and current ratings (to ensure safe operations)

- Temperature tolerance (to withstand harsh environments)

The Significance of Customization

Benefits of Custom 5-Pin Plugs

Customizing 5-pin electrical plugs offers numerous advantages:

- Tailored Solutions: Custom plugs can be designed for specific equipment, ensuring compatibility and optimal performance.

- Enhanced Functionality: Additional pins allow for more complex functions, like integrated sound controls or lighting management.

- Improved Reliability: Customized plugs are often built with high-quality materials, reducing the chances of wear and tear over time.

Applications in Various Industries

Audio Equipment

In audio equipment, such as mixers and amplifiers, custom 5-pin plugs are pivotal. They allow for:

- Balanced Audio Signals: Reducing noise interference, ensuring cleaner sound.

- Control Signals: Enabling remote adjustments to volume or effects.

- Multiple Channel Support: Facilitating a multi-channel audio system from a single plug.

Industrial Machinery

The design of custom 5-pin plugs also finds significant use in industrial applications:

- Robotics: Where multiple control signals need to be sent simultaneously.

- Heavy Equipment: Allowing operators to quickly connect/disconnect tools and machinery.

Bullhorn (Megaphone) Overview

The Role of Megaphones

A bullhorn is an essential device for amplifying the human voice, primarily used in public speaking situations, events, and emergency scenarios. It typically features:

- Input device: A microphone to capture sound.

- Amplification Circuitry: To boost sound levels.

- Speaker: To project sound over long distances.

The Importance of Custom 5-Pin Plugs in Bullhorns

Custom 5-pin plugs can significantly enhance the functionality and reliability of bullhorns:

- Multiple Inputs: They allow connections for additional microphones or audio sources.

- Power Management: Configuring power supply for the amplifying circuit efficiently.

- Control Mechanisms: Enabling remote volume control or feedback adjustment.

Designing Custom 5-Pin Plugs for Bullhorns

Identifying Requirements

When designing a custom plug for a bullhorn, several factors must be considered:

- Power Requirements: Determining the wattage needed to ensure efficient sound amplification.

- Environmental Conditions: Weatherproofing for outdoor usage.

- Ease of Use: Designing plugs that can be easily connected and disconnected.

Prototyping and Testing

The development process typically involves creating a prototype that is rigorously tested under various conditions to ensure reliability and performance. Testing should focus on:

- Durability: Can it withstand repeated use?

- Conductivity: Does it maintain a clean signal?

- Compatibility: Does it work seamlessly with existing equipment?

Challenges in Custom Plug Manufacturing

Standardization vs. Customization

One of the significant challenges in the production of custom 5-pin plugs is balancing standardization with customization. While standard plugs are widely used for convenience, tailored designs are often essential for unique applications. This may lead to complexities in manufacturing and supply chain logistics.

Cost Considerations

Custom components can be more expensive than standardized alternatives. Factors influencing cost include:

- Material Selection: Higher quality materials can improve performance but increase expenses.

- Production Volumes: Smaller runs can raise the cost per unit.

- Technical Expertise: Designing and manufacturing custom plugs often requires specialized knowledge.

Future Trends in 5-Pin Plug Design

As technology advances, the design and application of custom 5-pin plugs are poised to evolve. Key trends may include:

Increase in Wireless Applications

With the rise of wireless technology, traditional plugs face competition. However, hybrid solutions that combine wired and wireless capabilities could emerge.

Smart Integrated Systems

Future designs may incorporate smart technology, allowing plugs to communicate diagnostics or operational statuses, enhancing user experience and ease of maintenance.

Sustainability Considerations

There is growing awareness of environmental issues, leading manufacturers to explore sustainable materials and eco-friendly production processes.The importance of custom 5-pin electrical plugs is clear, especially in applications that require multiple connections for power and signals. Their role becomes even more crucial in devices like bullhorns, where amplifying sound effectively can be a matter of urgency or necessity. As technology continues to advance, the demand for customized, durable, and efficient electrical connectors will likely grow, shaping the future of connectivity across industries.

Custom 5 Pin Electrical Plugs: The Bullhorn Design Concept

Electrical plugs are an integral part of modern electrical systems, facilitating the connection between appliances and power sources. These connectors come in various designs and configurations, tailored to meet the specific needs of different devices and environments. Among these configurations, the 5-pin electrical plug stands out, especially when customized for unique applications.

Typically, electrical plugs have multiple pins that connect to corresponding sockets to provide power or signal. A 5-pin plug consists of five prongs, each fulfilling specific functions:

- Phase: In three-phase systems, typically, there are three phase pins, allowing the distribution of electrical power over long distances with higher efficiency.

- Neutral: The neutral pin serves as the return path for electric current; it balances the load in the circuit, contributing to overall system stability.

- Ground: The ground pin is essential for safety. It directs any leakage current away from devices and into the ground, reducing the risk of electrical shocks.

Applications of 5 Pin Electrical Plugs

5-pin connectors are commonly used in various settings, including:

- Industrial Machinery: Many machines require three-phase power for efficient operation, thus necessitating the use of 5-pin plugs.

- Audio/Visual Equipment: Custom 5-pin plugs are often designed for specialized AV systems, providing reliable connections for sound and video equipment.

- Heavy-Duty Appliances: Devices such as dryers and ovens benefit from the robust power delivery that 5-pin plugs can provide.

- IoT Devices: With the rise of IoT technology, customized electrical plugs are now being designed to support smart devices, integrating both power and data transmission.

The Bullhorn Design Concept

The term “bullhorn” often refers to a style or shape resembling a horn, which can be applied to the design of electrical plugs. This design can enhance usability and functionality in several ways:

- Ergonomics: Bullhorn-shaped plugs can be designed for easier handling, allowing users to connect and disconnect devices without much fuss. The shape can improve grip and manipulation.

- Space-Efficiency: The design can be tailored to occupy less space than traditional plugs, making them suitable for crowded or compact environments.

- Aesthetic Appeal: Custom designs can reflect a brand or user preferences, making equipment visually distinct and adding to the overall aesthetic of a workspace or home.

Benefits of Customization

Custom electrical plugs, particularly 5-pin bullhorn designs, offer several advantages:

- Tailored Solutions: Custom plugs can be designed to meet specific performance or aesthetic requirements, which is particularly useful in specialized industries.

- Enhanced Compatibility: Custom designs ensure that plugs fit seamlessly with existing equipment, promoting safety and reliability.

- Brand Identity: For businesses, custom plugs can be manufactured in brand colors or logos, enhancing visibility and brand recognition.

Manufacturing Considerations

When creating custom 5-pin electrical plugs, several factors must be considered:

- Material Selection: The choice of materials affects durability, conductivity, and safety. Common materials include thermoplastics for insulation and metals such as copper for conductivity.

- Regulatory Compliance: Manufacturers must ensure that custom plugs meet local and international safety standards (e.g., IEC, UL). Compliance is crucial for market acceptance and user safety.

- Quality Assurance: Rigorous testing procedures should be implemented throughout the manufacturing process to identify defects and ensure the plugs perform as intended.

- Production Volume: Custom designs can vary significantly in cost depending on the intended production volume. Bulk production typically reduces costs but may require higher initial investment in design and tooling.

Safety Considerations

Electrical safety cannot be overstated. When designing custom 5-pin plugs, particular attention should be paid to:

- Insulation: High-quality insulation prevents electrical shock and short circuits. Testing for heat resistance and environmental conditions is essential.

- Grounding: Ensuring that the ground pin is effectively connected and functioning correctly is vital for user safety.

- User Instructions: Clear instructional labeling on the plug can prevent misuse and encourage safe handling practices.

Market Trends and Future of Custom Electrical Plugs

As technology evolves, the demand for custom electrical plugs is expected to grow. Several trends are shaping the market:

- Smart Technology: As more devices become connected, there is a growing need for plugs that can handle both power and data transfer.

- Sustainability: Eco-friendly materials and energy-efficient designs are becoming priorities for manufacturers and consumers alike.

- Personalization: Customization goes beyond functionality; aesthetics and style are becoming increasingly important as consumers seek products that reflect personal identity.

- Integration of Safety Features: Innovative designs that incorporate safety features, such as overload protection or child-proofing, are gaining traction.

Emerging Trends in Bullhorn Technology

Custom 5-pin electrical plugs, particularly those featuring a bullhorn design, represent the intersection of functionality, safety, and aesthetics in electrical engineering. As industries evolve and technology expands, the demand for these specialized connectors will only continue to grow. By focusing on customization, manufacturers can meet specific needs, enhance user experience, and maintain regulatory compliance.

As we move forward into an era increasingly reliant on technology, the importance of reliable, safe, and customized electrical solutions cannot be overstated. Custom electrical plugs will play a crucial role in supporting innovations across diverse sectors, ensuring that connections remain efficient, safe, and user-friendly.

FAQs on Custom 5-Pin Electrical Plugs

1. What is a 5-pin electrical plug?

A 5-pin electrical plug is a type of connector that has five pins used to connect electrical devices to a power source or one device to another. It is often used for specific applications that require multiple connections, such as in industrial or audio equipment.

2. What are the typical applications for custom 5-pin plugs?

Custom 5-pin plugs can be used in various applications, including:

- Audio and video equipment

- Industrial machinery

- Automotive wiring

- Medical devices

- Custom electronics and prototypes

3. What materials are commonly used in manufacturing custom 5-pin plugs?

Custom 5-pin plugs can be made from various materials, including:

- High-quality plastics (such as nylon or polycarbonate)

- Metals (such as brass or aluminum for pins)

- Rubber for grips or contacts

Each material is selected based on durability, electrical conductivity, and environmental resistance.

4. What factors should be considered when designing a custom 5-pin plug?

When designing a custom plug, consider:

- Electrical specifications (voltage, current ratings)

- Pin configuration and arrangement

- Mechanical strength and durability

- Environmental factors (temperature, moisture, chemical exposure)

- Compliance with industry standards (e.g., UL, IEC)

5. How do I ensure regulatory compliance for custom plugs?

To ensure compliance:

- Understand local and international electrical safety standards.

- Work with certified manufacturers familiar with electrical certification processes.

- Consider testing and certification from recognized testing labs.

6. Can I design a 5-pin plug to be watertight or dustproof?

Yes, custom plugs can be designed to meet IP (Ingress Protection) ratings for water and dust resistance. This typically involves sealing techniques and appropriate materials.

7. What is the processing time for custom orders?

The processing time can vary depending on complexity, materials, and manufacturer workloads. Usually, it can range from a few weeks to several months.

8. Can I request prototypes of custom plugs?

Yes, many manufacturers can provide prototypes for testing before full-scale production. This is a valuable step to ensure design efficacy and identify potential issues.

9. What is the typical cost of custom 5-pin plugs?

Costs can vary widely based on design complexity, material choices, quantity, and manufacturing techniques. It’s best to request quotes from multiple suppliers.

10. Who can help me with the design and manufacturing of custom plugs?

You can reach out to specialized electrical component manufacturers or design firms with experience in connector design. Ensure they have the capability to meet your specific technical requirements.

Conclusion

Creating custom 5-pin electrical plugs requires careful consideration of various technical and regulatory aspects. Always conduct thorough research and collaborate with experienced professionals to ensure the best results for your project. If you have further questions or need specific advice related to your project’s needs, please feel free to ask!

For more Information About Gadget visit Digitalresearcher